How ScaleBuster Improves Biogas Filtration

1. Electrostatic Agglomeration of Particles

ScaleBuster alters the ionic charge of suspended solids and moisture droplets.

This causes fine particles to agglomerate into larger clusters, making them easier to capture in coalescing and particulate filters.

Result: Reduced filter loading and improved separation efficiency.

2. Scaling Prevention

In biogas systems, calcium, magnesium, and other minerals can precipitate and form scale on filter surfaces and pipelines.

ScaleBuster disrupts the crystallization process by modifying the electrochemical environment, preventing hard scale formation.

Result: Longer filter life, reduced maintenance, and better flow consistency.

3. Enhanced Moisture Separation

Charged droplets tend to coalesce more readily, improving the performance of demisters and coalescing filters.

This is especially valuable in humid biogas streams where water vapor can condense and carry corrosive compounds.

4. Protection of Downstream Equipment

By reducing particulate and scale load, ScaleBuster helps protect compressors, membranes, and catalysts from fouling and abrasion.

This leads to lower operational costs and improved system uptime.

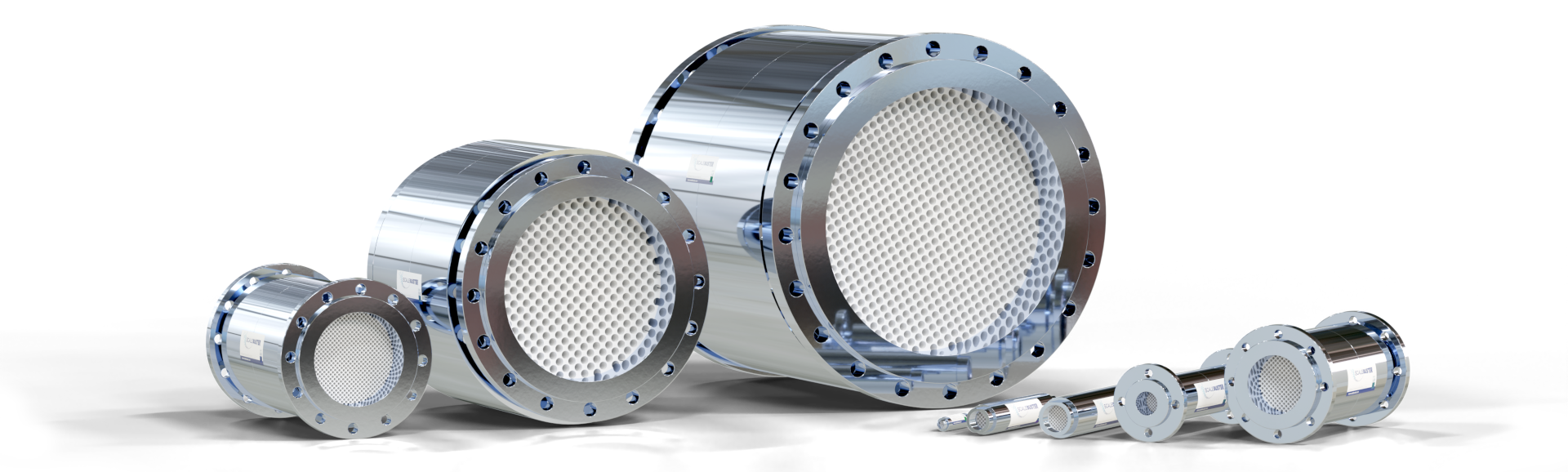

Ion-Asia Group: System Integrator and Distributor for ScaleBuster Technology

“Ion-Asia Group is proud to serve as the official system integrator and distributor for ScaleBuster technology across key industrial sectors. With deep expertise in water, air, and biogas purification, Ion-Asia ensures seamless deployment of ScaleBuster’s electrostatic conditioning systems to enhance filtration performance, reduce scaling, and extend equipment life. Our tailored integration approach supports applications ranging from municipal water treatment to advanced biogas recovery, delivering sustainable and cost-effective solutions to clients worldwide “